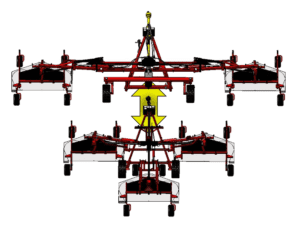

TD92

Tri-Deck Finishing Mower

CUTTING WIDTH

22'

CUT HEIGHT RANGE

3/4" to 5"

RECOMMENDED PTO H.P.

45 to 70

OVERVIEW

Since its introduction in 1990, Progressive’s 22 foot wide TD92 Tri-Deck Rotary Finishing Mower has become the benchmark mower of the natural grass industry. It is considered to be the most productive and cost effective wide-area natural grass mower available while delivering a quality of cut, second to none. Following extensive customer input, the Next Generation TD92 raises the bar even higher with new features that will enhance productivity and further reduce ongoing maintenance requirements and cost. The Next Generation TD92 is available with either painted or galvanized, bolt-on deck shells. Proudly built in North America, some of the standard features of the Next Generation TD92 include: enhanced clipping discharge, Maintenance Free Blade Spindles, extended 100 hour PTO Shaft Greasing intervals and fewer grease fittings than prior models. Four different OEM blades are available to match local growing conditions. Retaining many of the same components and design features that have been field proven on several thousand TD92’s, means that there is more time cutting, less time maintaining and more money in your pocket each day! The Next Generation TD92 raises the bar to new heights as the Better Built Choice!

AVAILABLE IN PAINTED OR GALVANIZED DECK SHELL FINISH

BENEFITS

- Lowering the Cost of Operation:

By always striving to improve, Progressive have introduced many innovations that have lowered the cost of natural grass production.

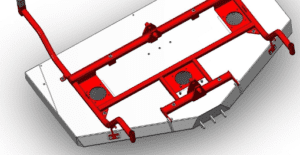

READ MORE - Bolt-on Deck Shell: Painted or Galvanized Versions Available:

For producers who grow in sandy, or acidic soil conditions, the bolt-on design allows for inexpensive replacement of the deck shell if necessary.

READ MORE - Excellent Flotation and Easy Height Adjustment:

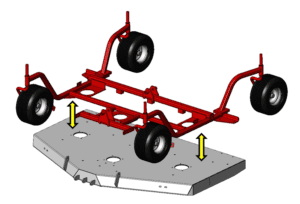

The TD92 is easy on the turf. Low ground pressure is achieved with 12 large, floatation tires. HOC adjustment is made using a combination of 3/8″ and 1″ spacers to achieve the 1″ to 5″ HOC cut range.

READ MORE - Designed Today for Convenience Tomorrow:

It is a well-known fact that many TD92’s remain in active service after operating 20 years plus in the field!

READ MORE - Reliable, Proven, Productive:

Our backwards compatibility strategy of parts and designs is the right approach for our customers, as many of the key components we use in our current production will fit older mowers; including gear boxes, spindles and PTO shaft among many other items.

READ MORE

SPECIFICATIONS

| Part Number: | 629222 (Painted Decks) 629222G (Galvanized Decks) (North America) / 629222C (Painted Decks) 629222GC (Galvanized Decks) (Worldwide) |

| Recommended PTO H.P.: | 45 to 70 |

| Mowing Capacity: * (Assumes no overlap or turning) | 2 mph 5.4 acres per hour * 4 mph 10.7 acres per hour * 6 mph 16 acres per hour * 7.5 mph 20 acres per hour * |

| Cut Height Range: | 3/4" to 5" in 3/8" steps |

| Cutting Width: | 22' |

| Turning Radius: | Zero Turn |

| Transport Width: | 9' 6" |

| Transport Tires: | P275 / 60R 15 Automotive Radials |

| Transport Height: | 10' |

| Weight: | 4100 lbs |

| Transport Length: | 15' |

| Std. Equipment: |

|

| Opt. Equipment: |

|

100 hour Greasing Interval

100 hour Greasing Interval Bolt-on Decks

Bolt-on Decks Heavier Spindle Mounting

Heavier Spindle Mounting Now Deck Cleaning Is Easier Than Ever

Now Deck Cleaning Is Easier Than Ever Heavier Construction = Longer Service Life

Heavier Construction = Longer Service Life

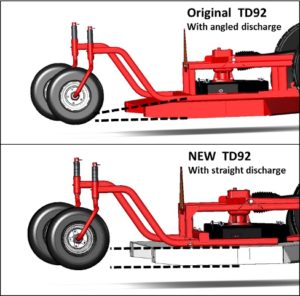

ipping Discharge

ipping Discharge Automatic Deck Locks

Automatic Deck Locks Designed Today for Convenience Tomorrow

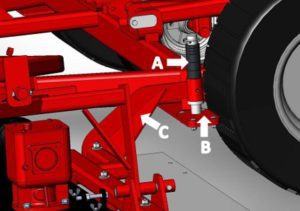

Designed Today for Convenience Tomorrow New Design Corner Pin

New Design Corner Pin Multi-position Hitch with 8 Different Height Positions

Multi-position Hitch with 8 Different Height Positions Progressive GROWS with your business!

Progressive GROWS with your business! Gear Boxes

Gear Boxes