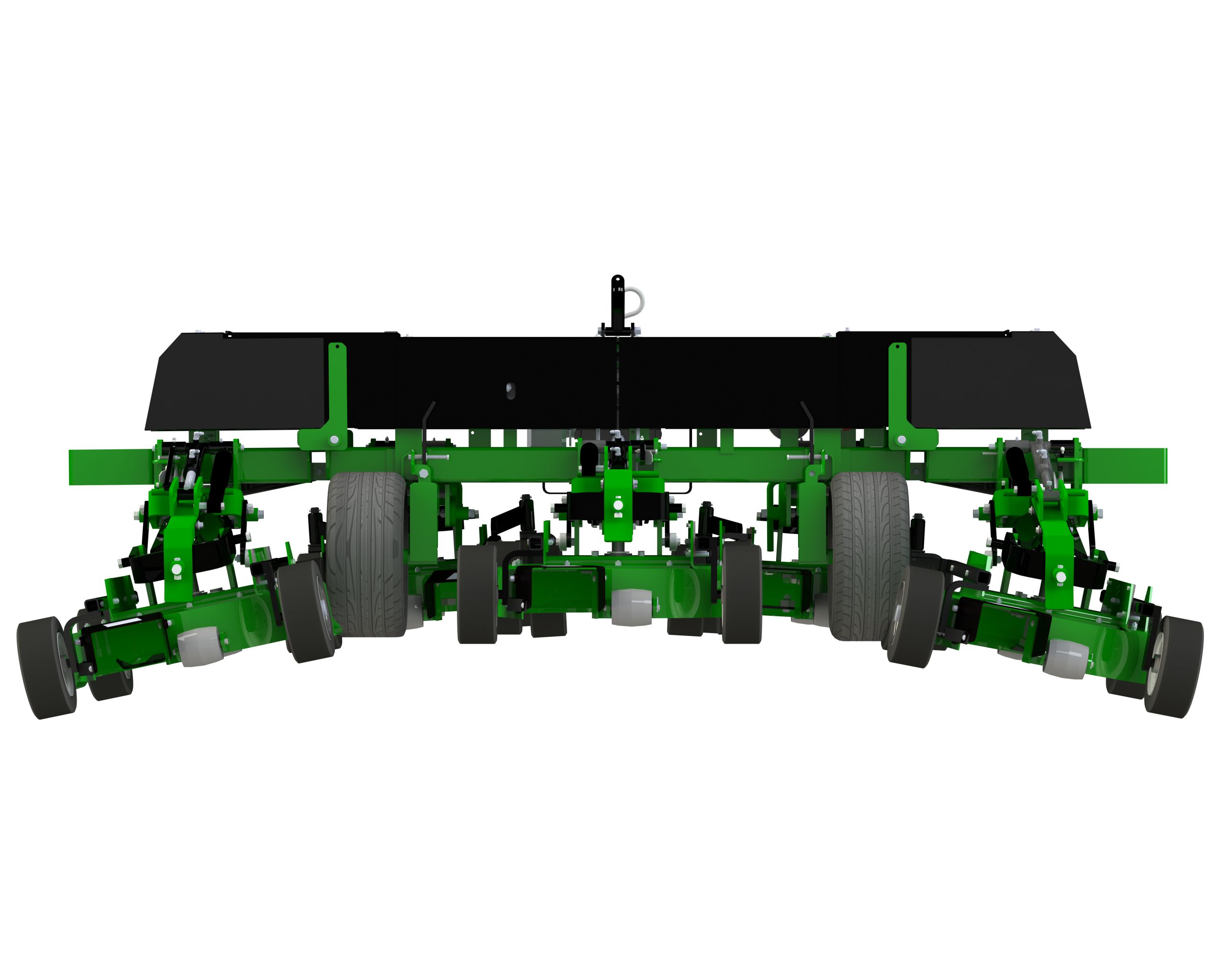

Pro-Flex 120

Contour Rough/Finishing Mower

CUTTING WIDTH

10'

CUT HEIGHT RANGE

1' to 3 1/4"

RECOMMENDED PTO H.P.

30 to 40

OVERVIEW

The Pro-Flex 120 is the most widely used pull-behind contour finishing mower. It has become the 'go-to' contour and rough mower due to its reliability, a 10' wide cut, and its versatility. With 5 independent floating decks, the Pro-Flex 120 will easily follow contour changes that are found on golf courses and campuses, producing a uniform quality cut that is demanded by Superintendents and members alike. The Pro-Flex 120 has several standard features that are important on a pull-behind contour mower, but are only available from Progressive! Utilizing the tractor for other tasks is a key advantage so we made connecting a Pro-Flex 120 to the tractor easy, thanks to an adjustable clevis, a low tongue weight, and an auto-lock PTO shaft. Originally introduced in 1999, the Pro-Flex 120 is well known as a durable, reliable rotary finishing mower that is now easier to maintain than ever before. The Pro-Flex 120 is “The Better Built Choice”.

BENEFITS

- Contour mowing:

Ultimate contour following due to five independent decks, allowing for a world-class cut and excellent clipping dispersal.

READ MORE - Ideal for making a stepped or a transition first-cut:

Being able to quickly and easily set each individual deck height gives the opportunity to do two jobs in one pass!

READ MORE - Pro Lift-N-Turn™ :

An industry exclusive feature – not found on other contour mowers! Pro Lift-N turn™ allows the decks to be raised slightly off the ground with the PTO still engaged. Crossing a cart path or other minor obstacles has never been easier.

READ MORE - Smart by design:

Innovative designs only found on Progressive mowers, help our customers do more in less time and at less cost!

READ MORE - Easy Routine Maintenance:

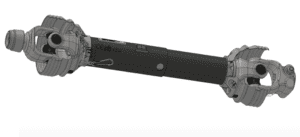

Our goal is to keep our customers mowing and not spend time performing routine maintenance. Reducing the number of grease points and using extended service interval PTO shafts are but two of the ways we minimize maintenance time and cost.

READ MORE

SPECIFICATIONS

| Part Number: | 601205 (Red) or 602711 (Green) (North America) / 601205D (Red) or 602711 (Green) (Worldwide) |

| Recommended PTO H.P.: | 30 to 40 |

| Mowing Capacity: * (Assumes no overlap or turning) | 4 mph 4.4 acres per hour * 6 mph 6.5 acres per hour * |

| Cut Height Range: | 1" - 3 1/4" |

| Cutting Width: | 10' |

| Turning Radius: | 16" uncut circle |

| Transport Width: | 8' 6" |

| Transport Tires: | 18.5 X 8.5 - 8 4ply |

| Transport Height: | 4' 2" |

| Weight: | 2075 lbs |

| Transport Length: | 11' |

| Std. Equipment: |

|

| Opt. Equipment: |

|

Versatile – A Fairway and a Rough Mower In One:

Versatile – A Fairway and a Rough Mower In One: Narrow transport width:

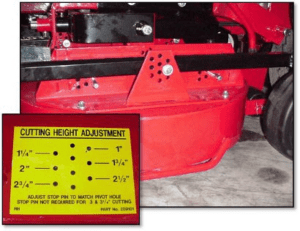

Narrow transport width: Easy change height adjustment:

Easy change height adjustment: Now Easier to Operate Than Ever Before!

Now Easier to Operate Than Ever Before! Automatic Wing Cylinder Lock Valve

Automatic Wing Cylinder Lock Valve Automatic Drive Belt Tensioning

Automatic Drive Belt Tensioning Lowering the Cost of Routine Maintenance

Lowering the Cost of Routine Maintenance Maintenance Free Blade Spindles

Maintenance Free Blade Spindles