TDR-12

Tri-Deck Roller Finishing Mower

CUTTING WIDTH

12'

CUT HEIGHT RANGE

1/2" to 4"

RECOMMENDED PTO H.P.

25 to 40

OVERVIEW

Progressive’s 12 foot Tri-Deck Roller Mower (TDR-12) is designed to maintain wide area mowing venues that require a superlative after cut appearance. The superior quality of cut, coupled with the TDR-12’s rugged construction, ease of maintenance and use give the TDR-12 the versatility to tackle a wide variety of mowing applications in parks, sports fields, and corporate campuses. The TDR-12’s full length rollers, which allow the mower to cut as low as ½” while simultaneously rolling and striping the mowing surface. Higher mowing speeds are often possible as the bounce from pneumatic tires are eliminated, making quick work of big jobs. Cutting heights are quick and simple to set with the supplied tool to any height from ½” to 4”. The TDR-12 is another example of the ingenuity and quality that goes into producing a durable, reliable rotary finishing mower that is easy to maintain. The TDR-12 is not only a Value and Performance leader, it is “The Better Built Choice”

BENEFITS

- Pro Lift-N-Turn™:

An industry exclusive feature – not found on other contour mowers! Pro Lift-N turn™ allows the decks to be raised slightly off the ground with the PTO still engaged. Crossing a cart path or other minor obstacles has never been easier.

READ MORE - Superior Cut Quality and Striping:

TDR-12’s high tip speed blades provide superior cut quality while heavy duty rollers produce bold recognizable stripes.

READ MORE - Worry Free Maintenance:

Maintenance free blade spindles, and PTO Shafts requiring lengthy intervals between greasing, reduces maintenance but provides you with the same reassurance of performing daily maintenance.

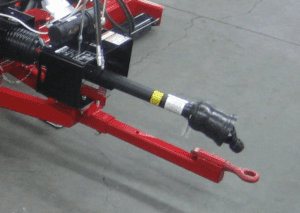

READ MORE - PTO Connection:

The Constant Velocity (CV) input PTO and auto-lock PTO coupler makes connecting the mower to a tractor easier while providing extra protection to the driveline by minimizing vibration when turning.

READ MORE

SPECIFICATIONS

| Part Number: | 528712B (North America) / 528712D (Worldwide) |

| Recommended PTO H.P.: | 25 to 40 |

| Mowing Capacity: * (Assumes no overlap or turning) | 2 mph 2.9 acres per hour * 4 mph 5.8 acres per hour * 6 mph 8.7 acres per hour * |

| Cut Height Range: | 1/2" to 4" |

| Cutting Width: | 12' |

| Turning Radius: | 24" uncut circle |

| Transport Width: | 7' |

| Transport Tires: | P275 / 60 R15 automotive tires |

| Transport Height: | 7' 6" |

| Weight: | 3400 lbs |

| Transport Length: | 14' |

| Std. Equipment: |

|

| Opt. Equipment: |

|

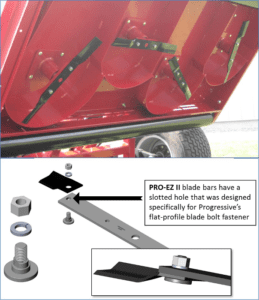

High Blade Tip Speed

High Blade Tip Speed Easy change height adjustment

Easy change height adjustment

C.V. input PTO system

C.V. input PTO system