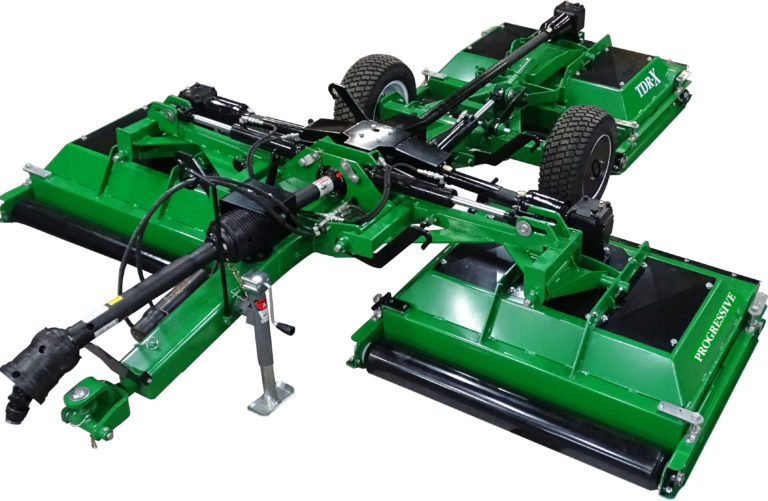

TDR-X

Tri-Deck Roller Finishing Mower

CUTTING WIDTH

10' 6"

CUT HEIGHT RANGE

3/8" to 3 3/8"

RECOMMENDED PTO H.P.

35 to 45

OVERVIEW

When building our first purpose built roller mower designed for both golf courses and sports fields, our customers wanted a mower that is nimble, durable, easy to use and maintain. Progressive Turf Equipment took those requests and created the TDR-X -'The way a contour mower should be designed'. It all starts at the front with the Adaptive Swivel Hitch that lets the mower work with the tractor instead of fighting with it, unlike a mower with a conventional hitch. Equipped with PRO-EZII blade tips, the TDR-X give an elite, professional finish that you can be proud of. Full width rollers on both the rear and front of each roller deck leaves stripe after beautiful stripe. Pro Lift-N-Turn lets you go over cart paths, roadways, and other obstacles while never having to shut off the PTO. Maintenance is a breeze with maintenance free spindles, 100-hr PTO shafts and a spring-less belt tightening system gives you piece of mind over the long term. The 3 decks float independently allowing the TDR-X to follow the contours of any golf course it cuts. Anyway you look at it, the TDR-X is: "the way a Contour Roller Mower Should Be Designed!"

BENEFITS

- Built Dependable:

Incorporating designs that are field proven and components that are used on much larger roller mowers – up to 30’ wide

READ MORE - Built Flexible:

6-way floating decks, and an Adaptive Swivel Hitch isolates the tractor from the mower allowing truer contour tracking – a Progressive exclusive!

READ MORE - Built Productive:

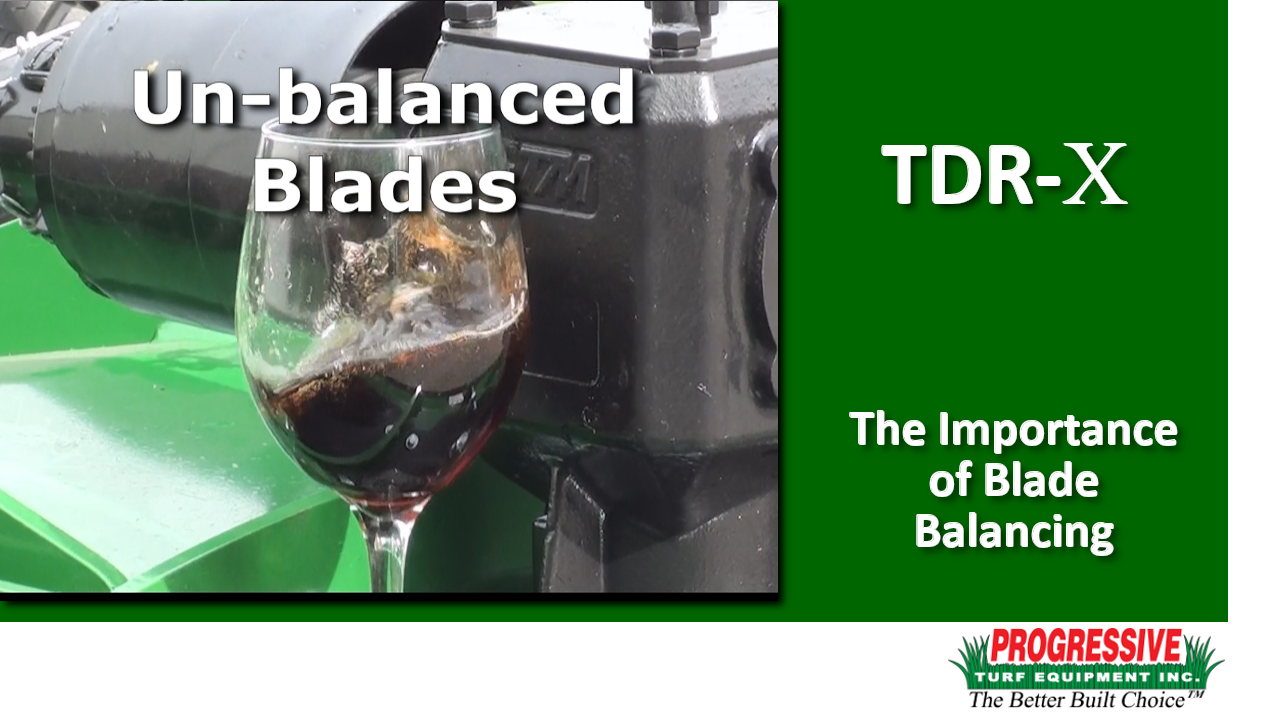

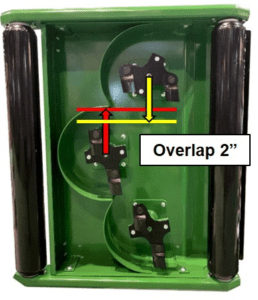

An industry leading blade overlap ensures a quality cut. The TDR-X is equipped with replaceable tip PRO-EZII blades as standard equipment.

READ MORE - Built Right:

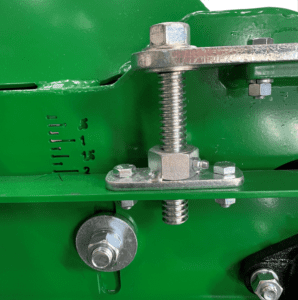

With Easy-set HOC adjustment, the exclusive Pro Lift-N-Turn, maintenance free blade spindles, extended service intervals and superior visibility to the work area the TDR-X is built for you!

READ MORE - Built Progressive:

Designed with the knowledge gained from over 20 years selling the industry’s most popular contour mower, the 5 deck Pro-Flex 120B

READ MORE

SPECIFICATIONS

| Part Number: | 549105 (Green) 549100 (Red) for North America and Worldwide |

| Recommended PTO H.P.: | 35 to 45 |

| Mowing Capacity: * (Assumes no overlap or turning) | 4 mph 5.0 acres per hour* 6 mph 7.6 acres per hour* |

| Cut Height Range: | 3/8" to 3 3/8" |

| Cutting Width: | 10' 6" |

| Turning Radius: | Zero Turn Capable |

| Transport Width: | 6' 6" |

| Transport Tires: | 23 x 8.5 - 12 6ply |

| Transport Height: | 6' |

| Weight: | 3250 lbs |

| Transport Length: | 11' 6" |

| Std. Equipment: |

|

| Opt. Equipment: |

|

Maintenance Free Spindles

Maintenance Free Spindles

Accurate Contour Mowing

Accurate Contour Mowing

atility – Thanks to a Better Discharge

atility – Thanks to a Better Discharge