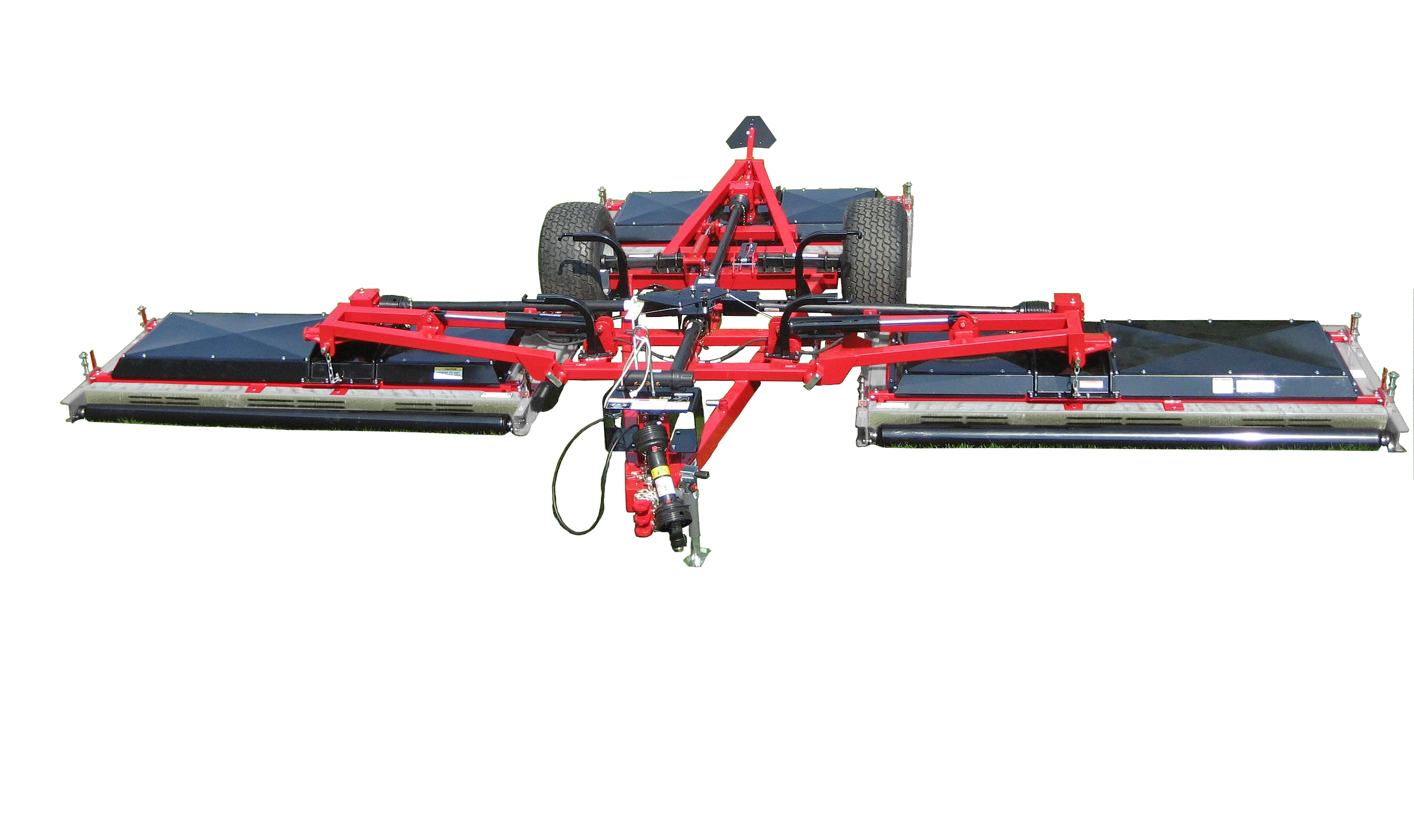

TDR-26

Tri-Deck Roller Finishing Mower

CUTTING WIDTH

25' 8"

CUT HEIGHT RANGE

1/2" to 4"

RECOMMENDED PTO H.P.

75 to 90

OVERVIEW

Maximizing productivity and reducing operating cost is what the TDR-26 / TDR-26G is all about. Designed with a ‘ideal sized’ 25’8” cutting swath, it balances the need for increased cutting capacity in a cost effective roller mower. The TDR-26 / TDR-26G is “easy on the turf” when turning at the headlands for more harvestable acres! Like all of our mowers, we designed the TDR-26 as if we were maintaining the mower ourselves, so simplifying and reducing service requirements was an important goal. Maintenance free blade spindles, with extended 100 hour PTO shaft greasing intervals and fewer grease fittings overall means more time cutting – less time maintaining. We kept it simple: no electro-hydraulic valves or sensors are required. For the ultimate in reliability, many components are fully interchangeable with Progressive’s field proven TDR-22 and TDR-30 models. Focusing on the needs of the natural grass producer, Progressive offers four blade options for the TDR-26. The producer can optimize their cut and maintenance costs depending upon the growing conditions by selecting between two fixed blades and two Pro-EZ Change replaceable tip blade options - all featuring Progressive’s renown cut quality

AVAILABLE IN PAINTED AND GALVANIZED DECK SHELL FINISH

BENEFITS

- Maximize Productivity:

Larger is better! With a wide productive 25’8″ cutting swath per pass, the TDR-26 / TDR-26G has been Field Proven as it has been operating in natural grass production applications since the summer of 2017.

READ MORE - Maintenance Free Features:

Simplifying service, reducing maintenance requirements while increasing productivity was a key design objective for the TDR-26!

READ MORE - Familiar Design:

The height of cut is easily adjusted from 1/2” to 4” using the 1” diameter acme thread adjusting screw, located out of harms-way above the side channel.

READ MORE - Ideal Front to Back Deck Balance:

Like its smaller brother (TDR22), the deck cradle pull points are positioned slightly ahead but much closer to the deck than how competitive models are designed.

READ MORE - Bolt-on Deck Shells: Painted or Galvanized Finish:

For producers who grow in sandy, or acidic soil conditions, the bolt on deck design allows for inexpensive replacement of the deck shell if necessary.

READ MORE

SPECIFICATIONS

| Part Number: | 520826 (Painted decks) 520826G (Galvanized Decks) for North America / 520826C (Painted Decks) 520826GC (Galvanized Decks) for Worldwide |

| Recommended PTO H.P.: | 75 to 90 |

| Mowing Capacity: * (Assumes no overlap or turning) | 4 mph 12.4 acres per hour * 6 mph 18.6 acres per hour * 7.5 mph 23 acres per hour * |

| Cut Height Range: | 1/2" to 4" |

| Cutting Width: | 25' 8" |

| Transport Width: | 104" |

| Transport Tires: | 33x16 LL-16.1 10pr |

| Weight: | 6200 lbs |

| Transport Length: | 17' |

| Std. Equipment: | The tractor is required to have a single hydraulic float circuit

|

| Opt. Equipment: |

|

Increased Productivity

Increased Productivity Maintenance Free Blade Spindles

Maintenance Free Blade Spindles 100 hour Greasing Interval

100 hour Greasing Interval HEX Drive Rollers and Sealed Bearings

HEX Drive Rollers and Sealed Bearings Height Adjustment

Height Adjustment Commonality of Components

Commonality of Components Ideal Front to Back Deck Balance

Ideal Front to Back Deck Balance

Bolt–on Deck Shells – In Either Painted or Galvanized Finishes

Bolt–on Deck Shells – In Either Painted or Galvanized Finishes